-

Mechanical Systems Design Course

Mechanical Systems Design Course  Materials and Manufacturing Course

Materials and Manufacturing Course System Control and Robotics Course

System Control and Robotics Course Environment and Energy Course

Environment and Energy Course

Mechanical Systems Design Course

This course aims to cover the basics of mechanical engineering, including mechanics of solids, kinetics of machinery, machine design, and manufacturing processes; to apply them to advanced areas, such as design of new materials, dynamic system design, molding processes, CAE, micro/nanostructure fabrication technology, MEMS, cell therapy; and to develop highly qualified and talented people in comprehensive machine/system design and in mechanical engineering as a whole.

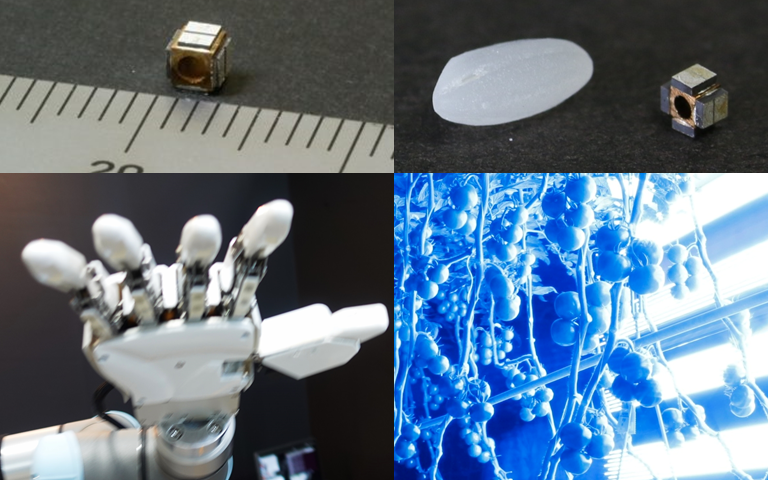

- MEMS/NEMS Processing Laboratory

- High Throughput Micro/Nano Engineering Laboratory

- Mechine Dynamics Laboratory

- Material and Structural Mechanics Laboratory

MEMS/NEMS Processing Laboratory

| HP URL | https://mems.me.tut.ac.jp/ |

|---|---|

| Keyword | Micro/nano fabrication, MEMS/NEMS, Lab-on-a-Chip |

| Affiliated faculty member |

Research summary

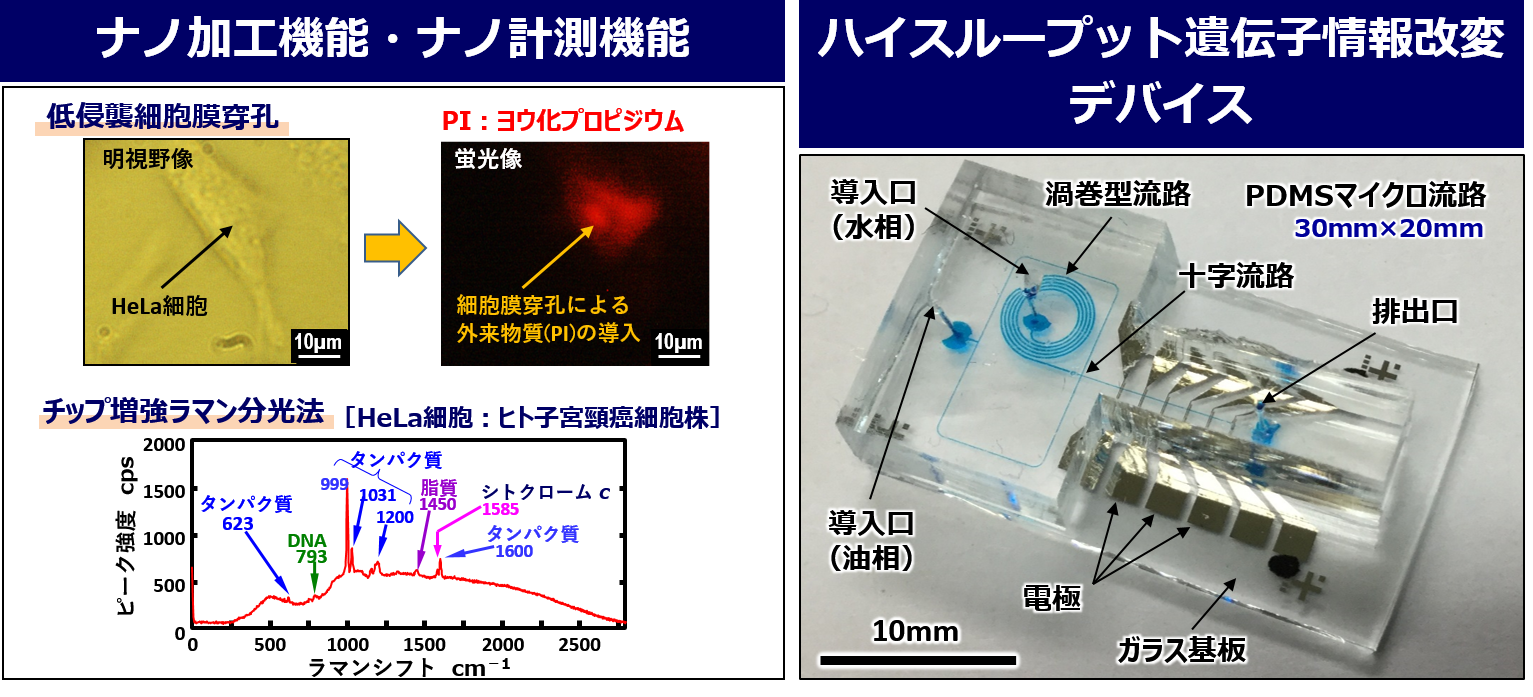

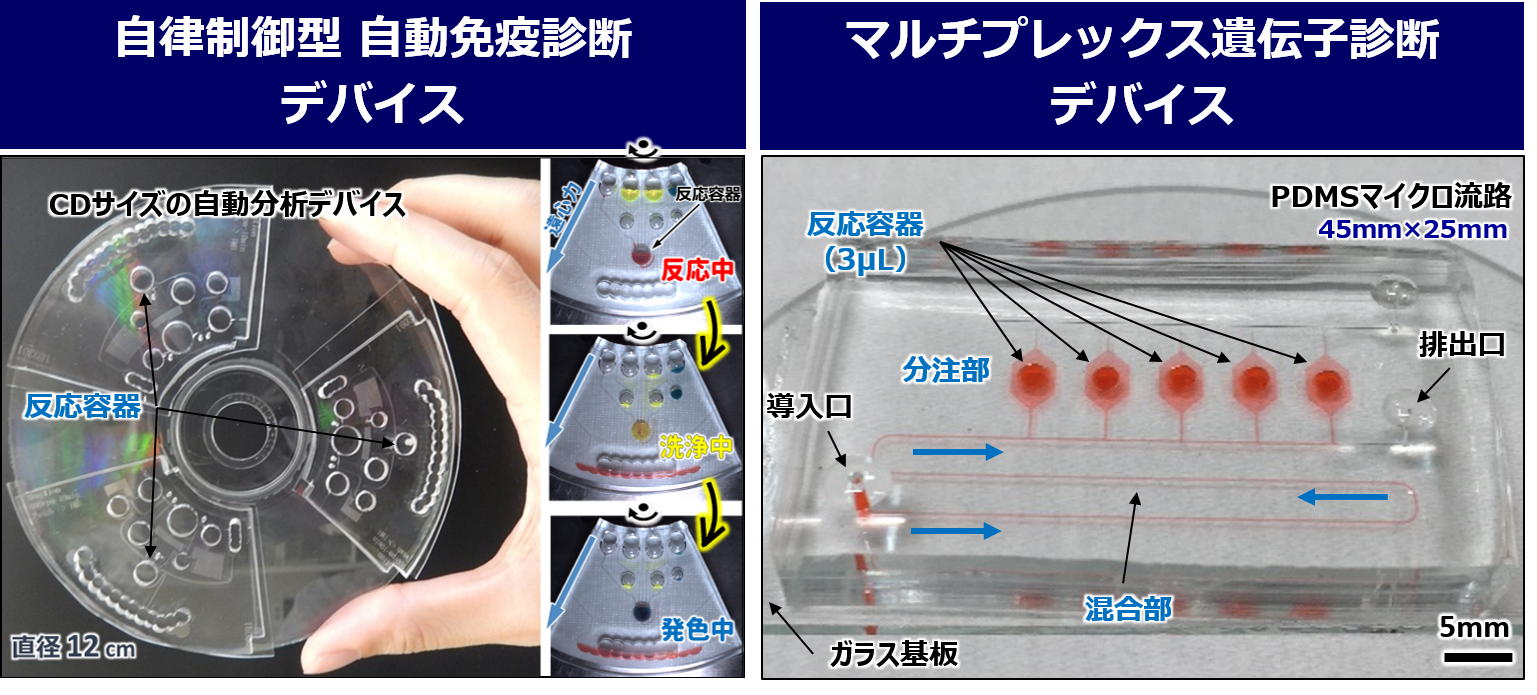

MEMS/NEMS Processing Laboratory studies the basics and applications of Micro Electro Mechanical Systems (MEMS). We use advanced micro/nano-fabrication and strive to create a new value by combining “mechanical engineering” and “life science.” Application fields are the development of MEMS devices/systems to support innovation in medicine and life science. Currently, our group focuses on four projects: (1) AFM-based nano-fabrication and measurement system for a single cell, (2) microfluidic-based electroporation system for designing cellular functions, (3) centrifugal microfluidic-based immunoassay system for blood testing, and (4) microfluidic-based detection system for simultaneous quantification of multiple nucleic acid targets. Our consistent concept is to “investigate MEMS technologies and create a bridge between MEMS and nano and biology.”

High Throughput Micro/Nano Engineering Laboratory

| HP URL | https://hmn.me.tut.ac.jp/ |

|---|---|

| Keyword | Cell Therapy, Biomicrosystem, Single Cell Processing |

| Affiliated faculty member |

Research summary

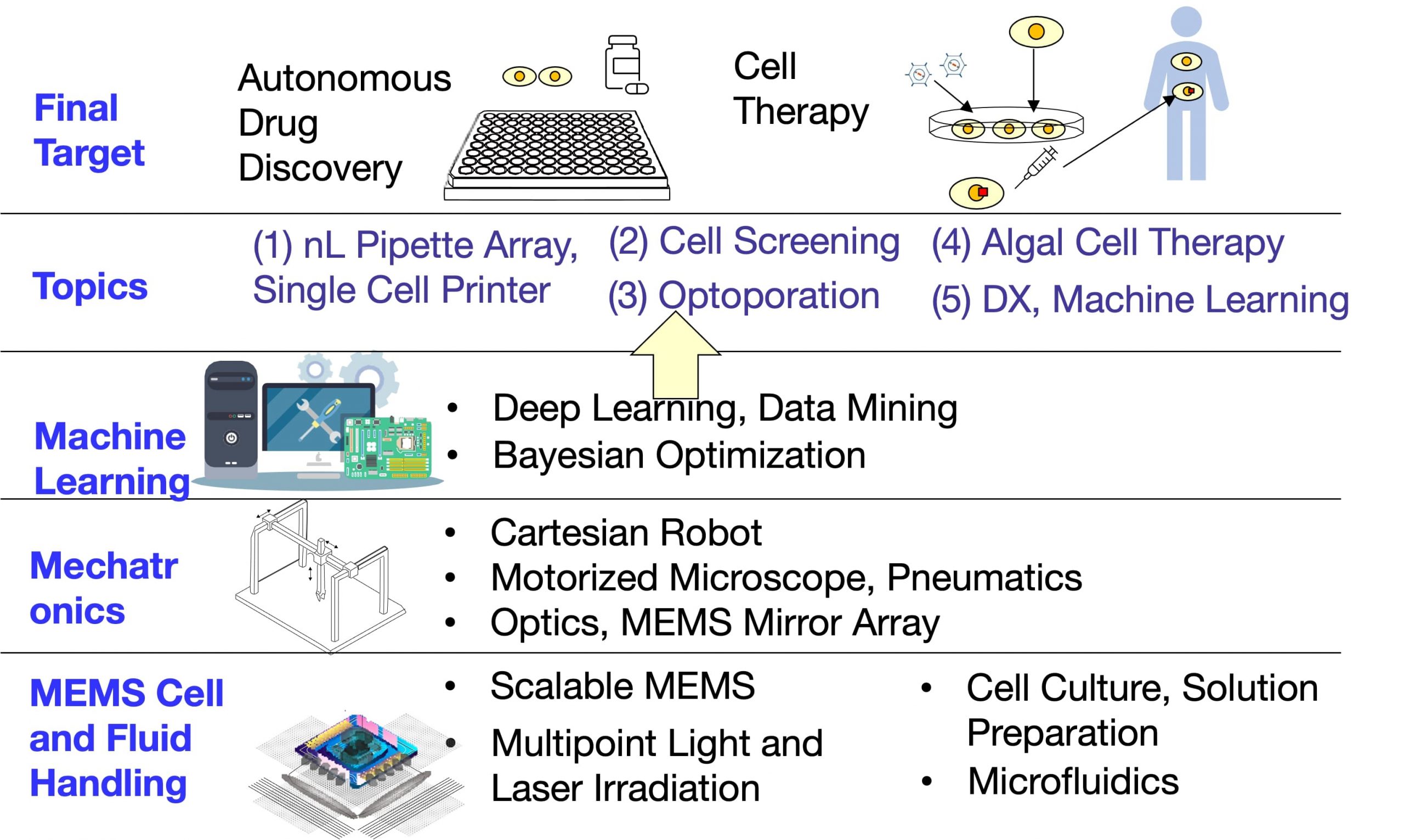

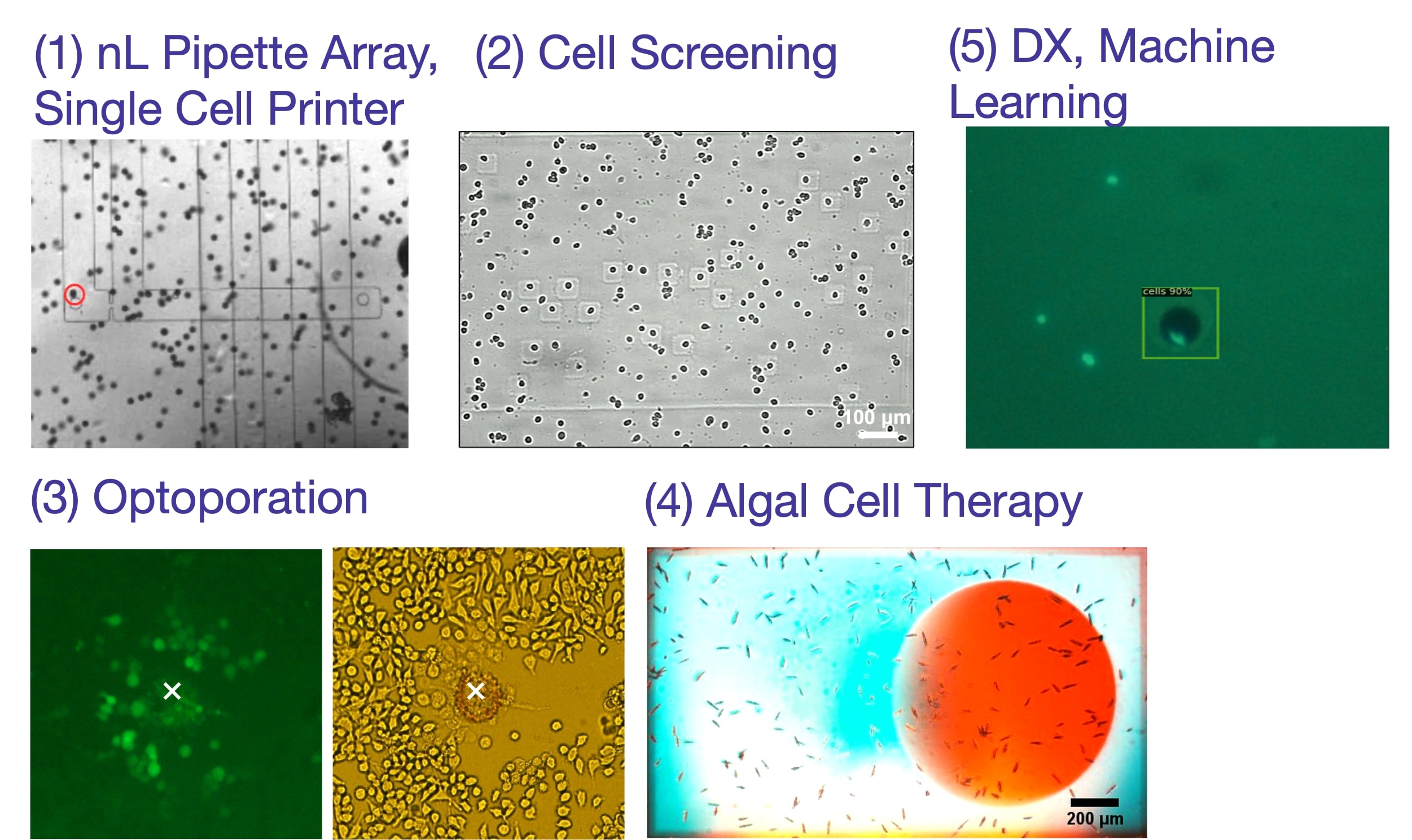

High Throughput Micro/Nano Engineering Laboratory integrates the power of micro/nano devices, mechatronics, and computer science to achieve high throughput of operations at the micro/nano scale. We are working on 3D printing of single cells and hydrogels, single cell screening using machine learning, high-volume intracellular delivery, and optical manipulation of microorganisms. We contribute to cell therapy, drug discovery, and sensing by enabling flexible manipulation of cells and microfluidics.

Machine Dynamics Laboratory

| HP URL | http://dynaweb.me.tut.ac.jp/ |

|---|---|

| Keyword | Vibration Engineering, Dynamic Design, Vibration Suppression |

| Affiliated faculty member |

Research summary

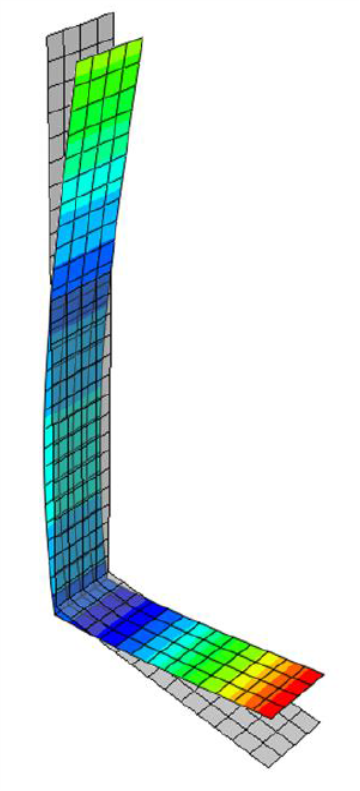

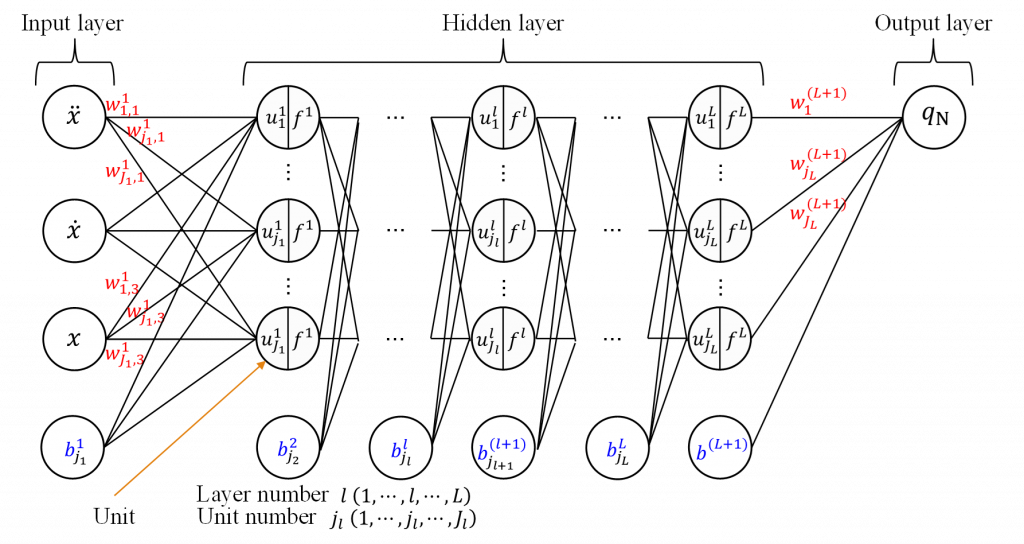

The basic philosophy of our laboratory is to contribute to the realization of a sustainable society based on vibration engineering. Therefore, we are conducting education and research on modeling, analysis, and design of artificial objects such as machines, equipment, and structures. Specifically, we investigate experimental modal analysis, structural health monitoring and diagnosis, identification of system property and characteristic parameters, vibration suppression and control. At this time, we also utilize methods based on data science such as Neural Network.

Material and Structural Mechanics Laboratory

| HP URL | http://solid.me.tut.ac.jp/ |

|---|---|

| Keyword | Materials engineering, Solid mechanics, Tribology |

| Affiliated faculty member |

Research summary

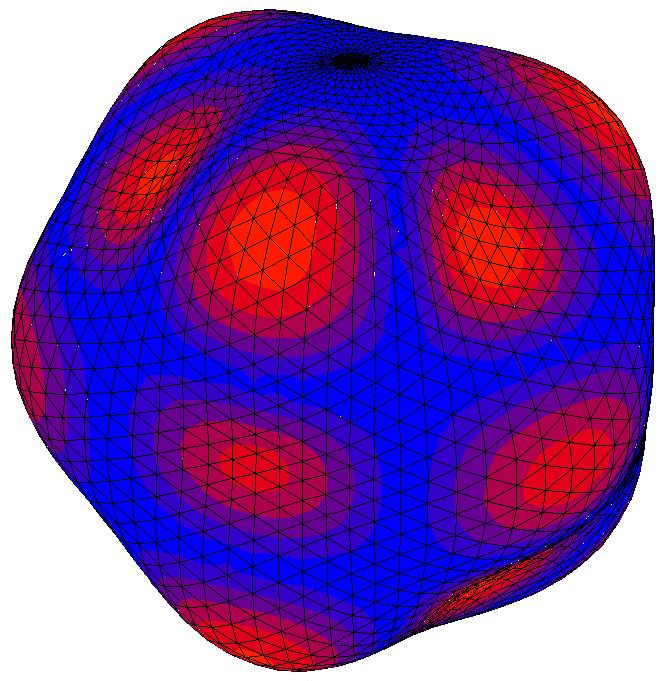

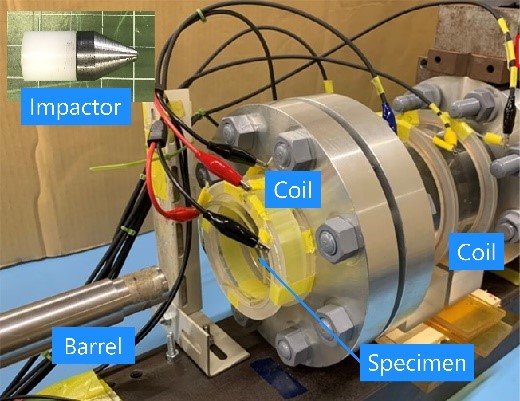

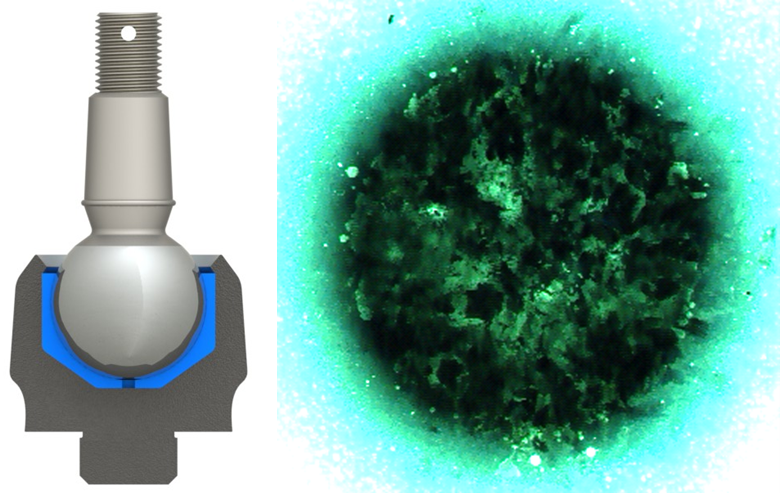

From the viewpoints of strength of materials, materials engineering, and tribology, we study, develop, and design the materials and structures suitable for various purposes by experimental, theoretical methods and numerical simulations. The research targets are polymer materials, metal materials, ceramic materials, and their composite materials from nano- and micro-size to large-scale mechanical structures. We also design and produce the new measuring instruments and develop the software.

Materials and Manufacturing Course

This course offers to teach the basics of new materials, material design, microstructural control, material evaluation, and processing. Student may explore control of multiscale structures of material and their evaluation, and the development of advanced processing technologies. The program aims to cultivate highly skilled professionals in the fields of materials and production processing, based on mechanical engineering.

- Materials Function Control Laboratory

- Development and Evaluation of High Strength Materials

- Material Assessment Laboratory

Materials Function Control Laboratory

| HP URL | http://martens.me.tut.ac.jp/ |

|---|---|

| Keyword | Steel, Lattice defects, non-equilibrium process |

| Affiliated faculty member |

Research summary

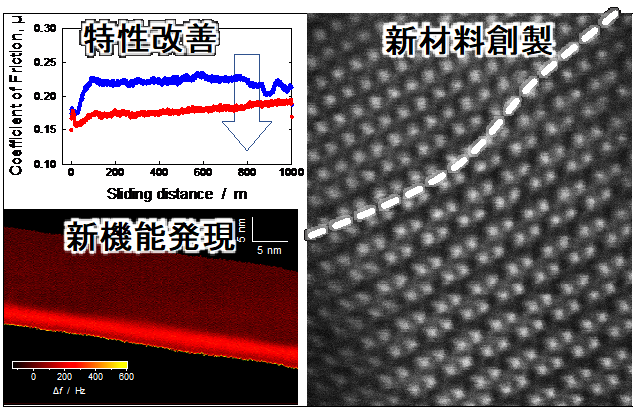

By introducing disordered region (lattice defects) into a metallic material having a crystal structure where constituent atoms are arranged in three dimensionally ordered structure, microstructure of metallic materials are controlled in Materials Function Control laboratory. We are developing new materials, revealing hidden function of materials, and improving existing properties by applying the microstructure control method using lattice defects.

Development and Evaluation of High Strength Materials

| HP URL | http://www.str.me.tut.ac.jp |

|---|---|

| Keyword | Severe plastic deformation, Microstructure control, Dynamic recovery, Biomaterials, Bulk Nanostructured Metals |

| Affiliated faculty member |

Research summary

The Development and Evaluation of High Strength Materials Laboratory conducts experimental studies on the strengthening, destruction, plastic deformation, and evaluation of metals and alloys. The Laboratory analyzes material structures and fracture mechanisms from the micro to the atomic level using electron microscopes and X-rays.

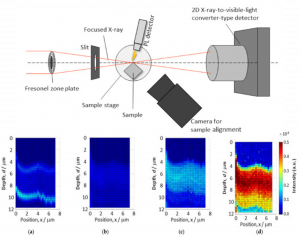

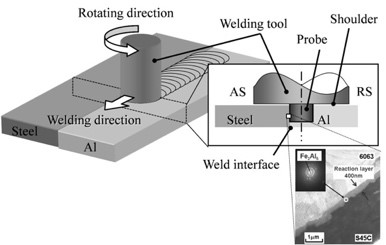

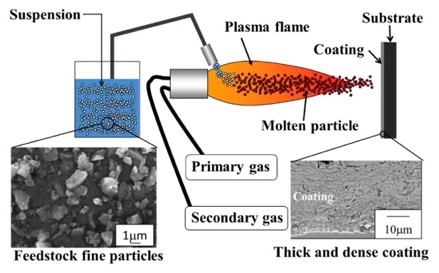

Material Assessment Laboratory

| HP URL | http://ma.me.tut.ac.jp/ |

|---|---|

| Keyword | 3-d deformation/failure, synchrotron source, nanotomography, metal/semiconductor, photovoltaic (PV), photoelectrochemistry (PEC) characterization, structure control, failure mechanism, Friction Stir Welding (FSW), Plasma Electrolytic Oxidation (PEO) |

| Affiliated faculty member |

Research summary

The education and research activities at the Material Assessment Laboratory are focused extensively on evaluating materials, particularly examining the processes of deformation and failure, as well as investigating the internal mechanisms of materials, including the fracturing of metals and the investigations of photoactive compound semiconductors (photovoltaics, photoelectrochemistry, and scintillation). Our goal is to develop innovative engineers who are proficient in materials assessment and characterization.

System Control and Robotics Course

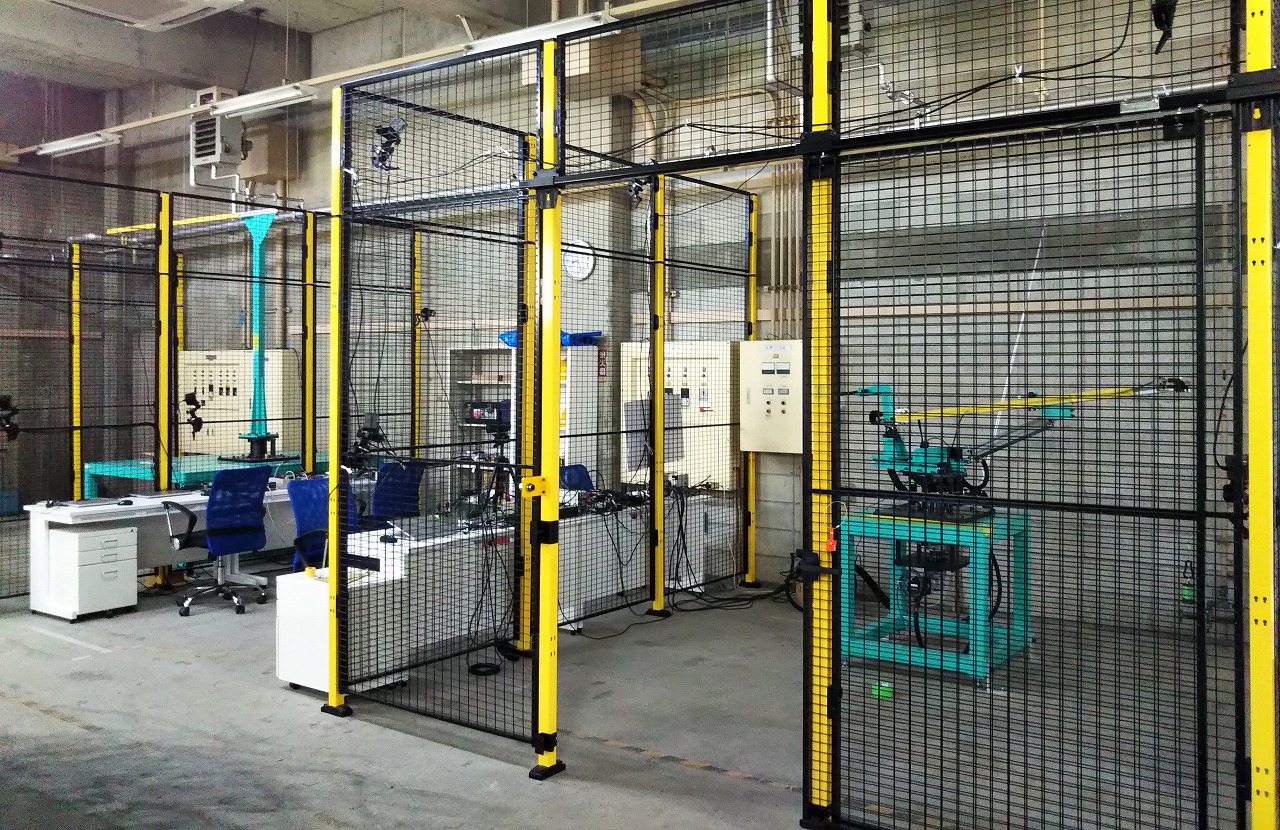

- Robotics and Mechatronics Laboratory

- Instrumentation Systems Laboratory

- Systems Engineering Laboratory

- Smart Materials Robotics Laboratory

Robotics and Mechatronics Laboratory

| HP URL | https://www.rm.me.tut.ac.jp/en/ |

|---|---|

| Keyword | Robotics, Mechatronics, Actuator |

| Affiliated faculty member |

Research summary

This research group studies elemental technologies such as mechanisms, control and sensors of robot and mechatronics systems, and their integration / fusion technology and their applications. In particular, this group has interest in methods for achieving both high usability such as good operability and maintainability and high performance such as high precision and high speed , improvement method under constrained environment so as to realize a practical and excellent exercise system.

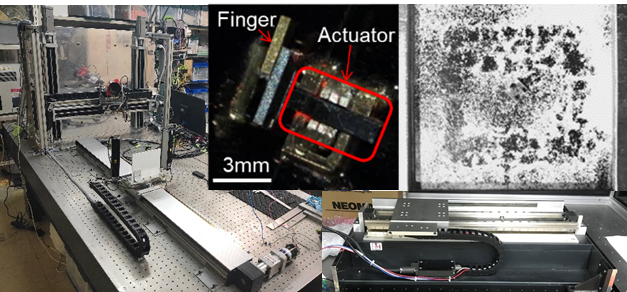

Instrumentation Systems Laboratory

| HP URL | https://is.me.tut.ac.jp/ |

|---|---|

| Keyword | Actuator, Sensing, Agritech |

| Affiliated faculty member |

Research summary

We are developing “Sensing technology” to measure the state of people and objects, and “Actuator” to drive motors and robots, and aiming to apply them to the fields such as medical care, rehabilitation, robots, automobiles, and especially to agricultural production. As an application in agricultural production, we are developing plant diagnosis/monitoring techniques which would realize advanced cultivation and labor management in intelligent greenhouses.

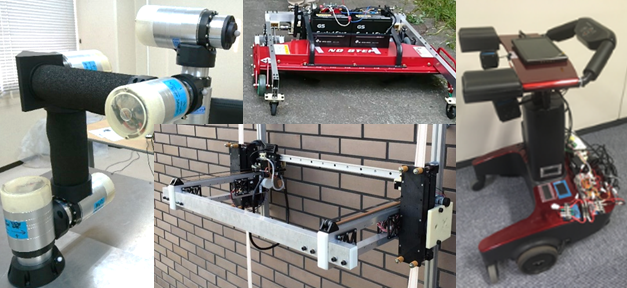

Systems Engineering Laboratory

| HP URL | http://ise.me.tut.ac.jp/index-e.html |

|---|---|

| Keyword | Optimization, Mathematical modeling, Control |

| Affiliated faculty member |

Research summary

Research interests include industrial applications of optimization, mathematical modeling and control theories. Current topics including industrial collaboration are energy-saving and precision control of machine tools and industrial robots; optimal motion generation and anti-sway control of industrial machines; autonomous mobile robot control; visual recognition of outdoor environment and natural objects; production and logistics scheduling.

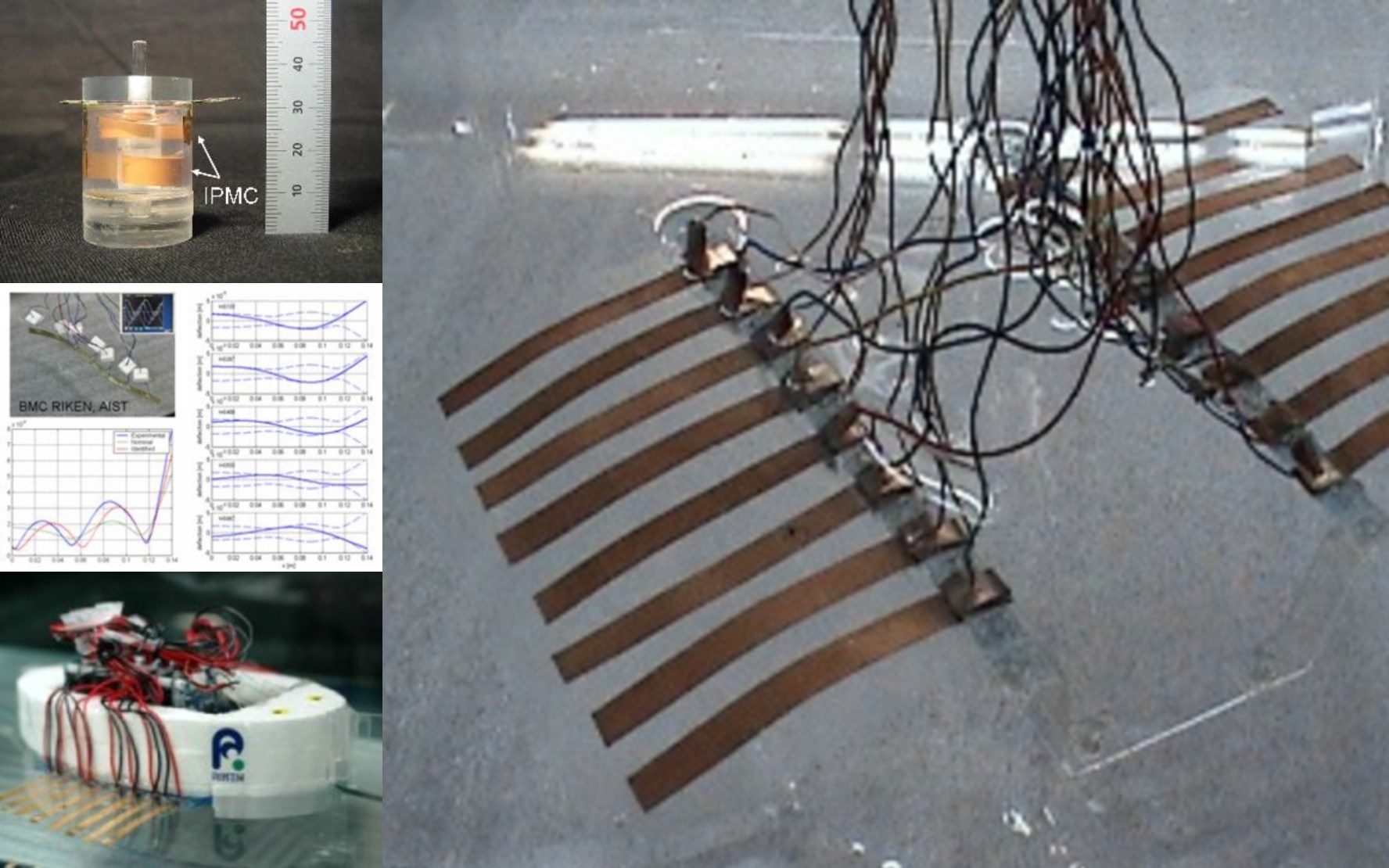

Smart Materials Robotics Laboratory

| HP URL | http://smr.me.tut.ac.jp/ |

|---|---|

| Keyword | Polymer actuators and sensors, soft robotics, vibration control |

| Affiliated faculty member |

Research summary

We are aiming for smart materials applications such as soft robotics including artificial muscle robots, industrial machines such as automobile devices. We utilize polymer actuators, polymer sensors, and piezoelectric materials as smart materials. Based on control engineering and physics, our research covers physics, mathematical modeling, simulation, control, mechatronics implementation using microcomputers, and robotic applications.

Environment and Energy Course

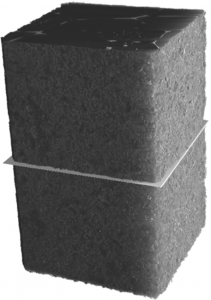

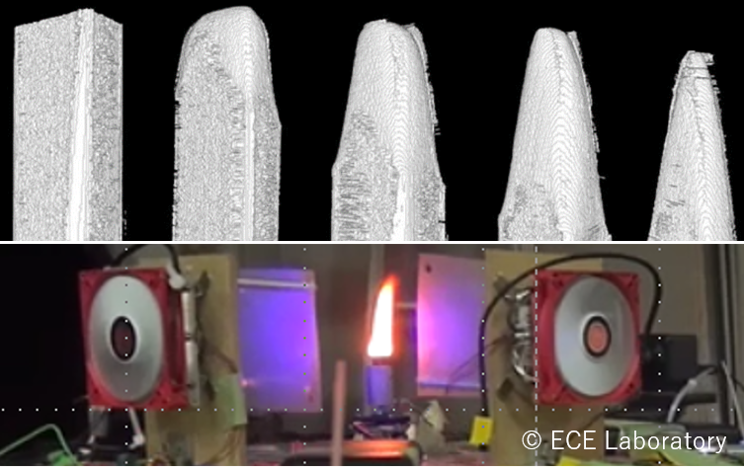

環境エネルギー変換工学研究室

| HP URL | https://ece.me.tut.ac.jp/wp/ |

|---|---|

| Keyword | Combustion,Fire,Scale Modeling |

| Affiliated faculty member |

Research summary

This laboratory aims to develop eco-friendly combustion technology with insights into combustion science. The eco-friendly combustion technology does not only mean improvement of energy efficiency of fossil fuel power generation, but also development of fire suppression technologies. Fire suppression technologies will contribute to reduction of carbon emissions as well as improvement of energy efficiency of fossil fuel power generation, since some researchers reported that the amount of wildfire emissions of carbon is equivalent to 20% of the mean annual global carbon emissions from fossil fuels. Unfortunately, the most common cause of fires is human activity such as burning debris, unattended campfire, and so on. Both technologies for improvement of energy efficiency and fire suppression play a key role in reducing carbon emissions for a sustainable future.

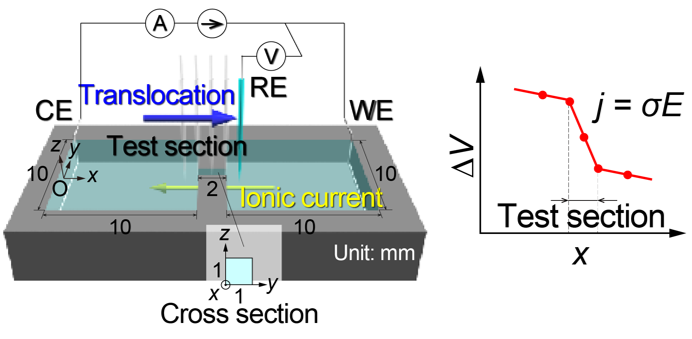

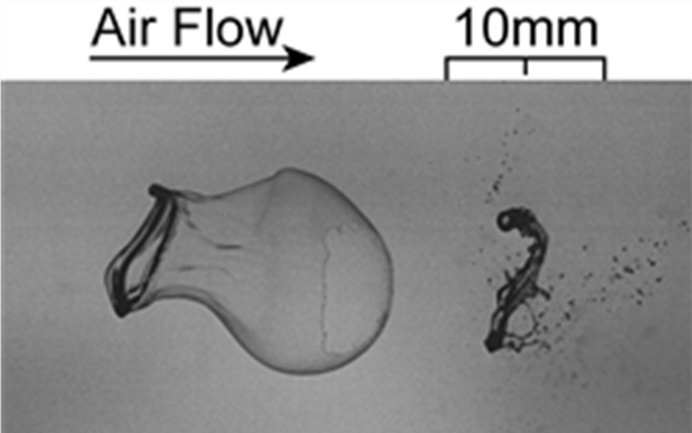

環境熱流体工学研究室

| HP URL | http://www.me.tut.ac.jp/tfe/ |

|---|---|

| Keyword | Micro- and Nanoscale Transport Phenomena,Thermo-Fluid Dynamics,Liquid Atomization |

| Affiliated faculty member |

Research summary

At the Thermo-Fluid Engineering Lab, focusing on various scale physicochemical phenomena found in nature, machinery, living organisms and so on, we are investigating dominant parameters from the viewpoint of heat, fluid, and mass transport, and are developing novel thermo-fluid devices for high efficiency and clean energy conversion systems. For example, focusing on molecular and ion transport phenomena in liquids, novel measurement methods of local concentration and flow fields are developed by using micro- and nanofluidic devices. For liquid atomization, details in the process are visualized using a high-speed video camera with custom-made equipment and are investigated by experimental and theoretical approaches.

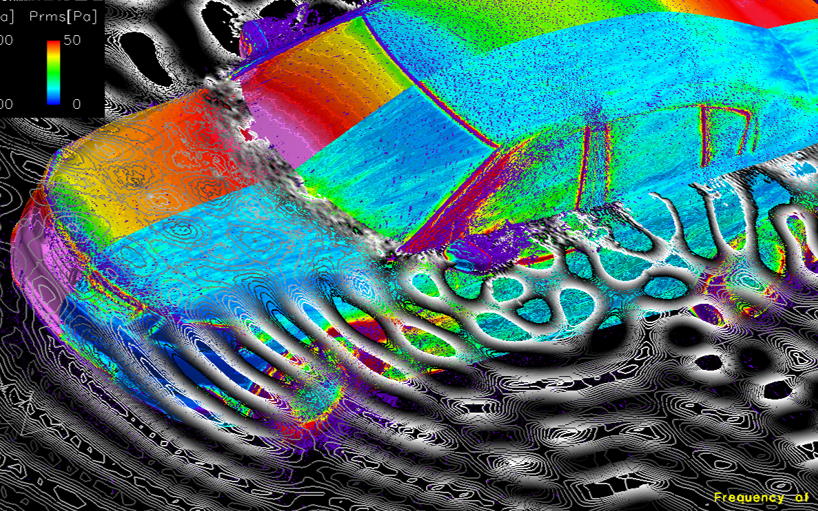

自然エネルギー変換科学研究室

| HP URL | http://aero.me.tut.ac.jp/profile1.html |

|---|---|

| Keyword | Fluid Mechanics,Aeroacoustics,Computational Fluid Dynamics |

| Affiliated faculty member |

Research summary

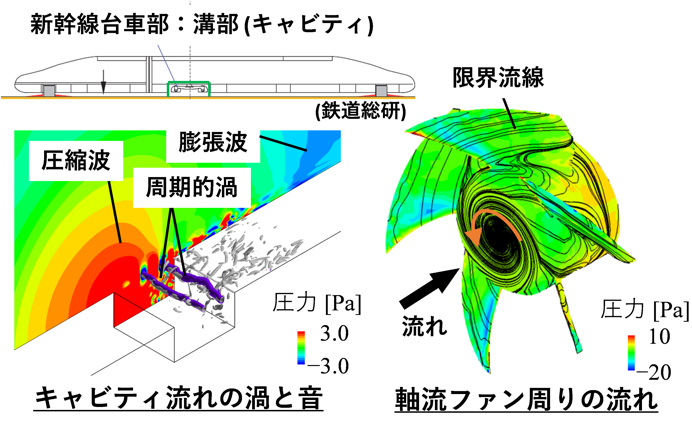

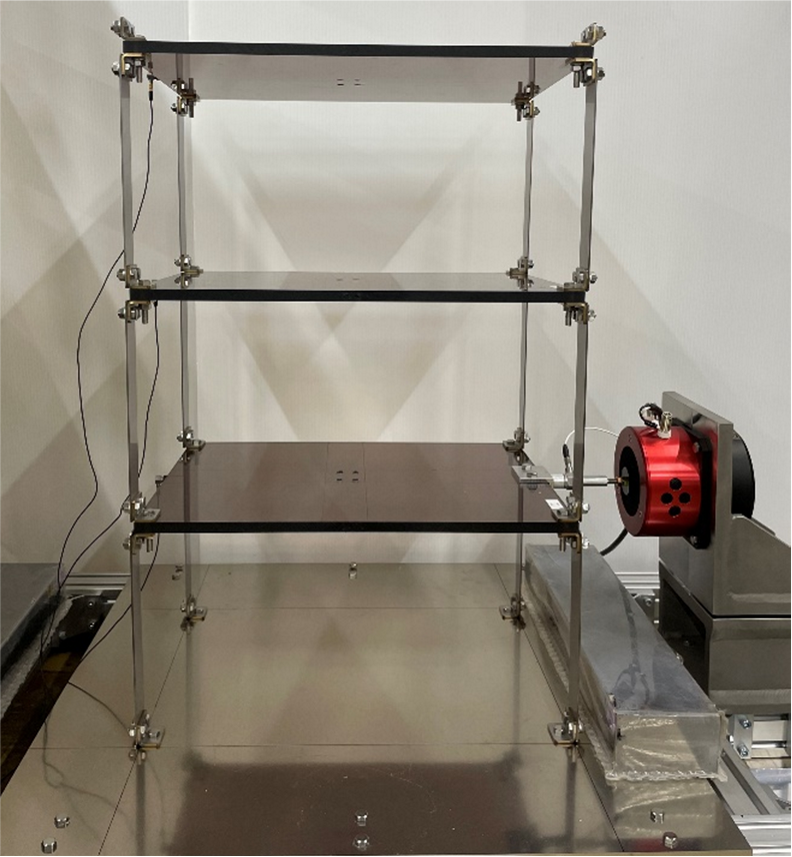

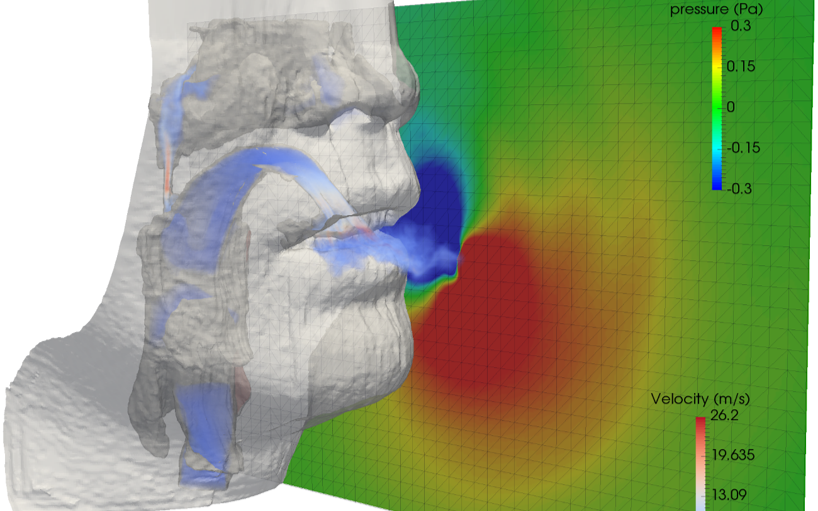

Our main target of research is airflow, sound, and natural energy in our surroundings, and we analyze them by using computers, wind tunnels, and anechoic chambers. In the computational analysis, we are developing a highly accurate prediction technique for the aerodynamic sound generation with the world’s largest-scale supercomputers. In the wind tunnels and anechoic chambers, we reproduce the airflow and sound generation around automobiles, oral cavities, and musical instruments. The reproduced flow and sound are measured and analyzed by hot-wire anemometry and microphones. By combining the experimental and computational analysis, we clarify the detailed mechanisms of aerodynamic sound generation.

省エネルギー工学研究室

| HP URL | https://ec.me.tut.ac.jp/en/ |

|---|---|

| Keyword | Fluid machinery,Electrohydrodynamics,Heat transport |

| Affiliated faculty member |

|

Research summary

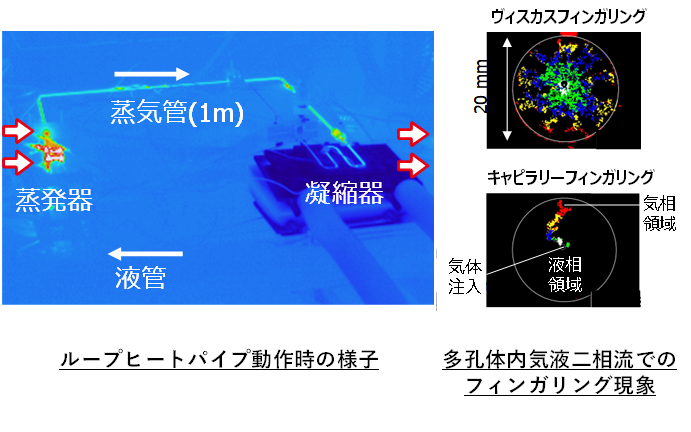

The laboratory performs the study on energy and resource saving including environmental load reduction. For fluid machineries such as hydraulic pumps and axial-flow fans, experiments and computations are conducted to achieve reduction of energy loss and noise. The laboratory proposes a new mathematical model for the dynamic characteristics of lubricating film in fluid power actuator motions. By utilizing electrohydrodynamic flows, the efficient pumps without impeller, actuators and heat control equipment are developed. The control of aerodynamic sound by a plasma actuator inducing flows via generation of plasma is investigated. The laboratory develops an electrostatic filter with the aim of removing minute contaminants from lubricating oils. Moreover, heat transport device without electric power such as loop heat pipe and thermoacoustic heat pump utilizing porous media is developed. The laboratory conducts visualization experiments to clarify heat transfer mechanism and unstable phenomenon related with liquid-vapor phase-change.